With the advancement of technology, there are more and […]

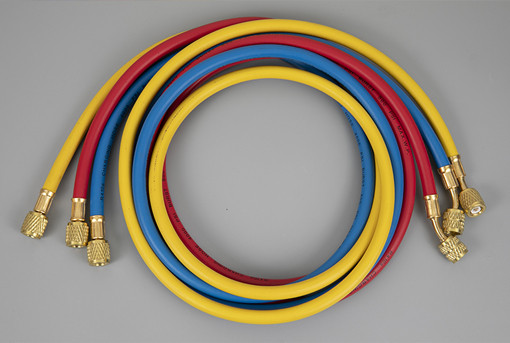

With the advancement of technology, there are more and more types of rubber hoses on the market. It is important to know how to choose the hose that suits you, but it is more important to know how to maintain and store rubber hoses. Due to the material, the rubber hose is aging all the time, but the degree is different, so it is particularly important to fully understand the reasons for the aging of the rubber hose.

1. Oxidation reaction

The oxidation reaction is one of the main reasons for the aging of the R410 refrigerant tube. This is because oxygen will oxidize with the molecules in the rubber, causing the molecular chain of the rubber to break or excessive cross-linking, which will cause the performance of the rubber to gradually weaken until the rubber is completely aging. But the air always contains oxygen, so the aging (oxidation reaction) of rubber is going on all the time.

2. Ozone

Ozone is more likely to cause the aging of the rubber tube. This is because ozone is more oxidizing and much larger than oxygen. However, the ozone content in the air is not too much, and only in certain places will it affect the rubber tube. Therefore, as long as the working environment and storage environment of the main rubber tube, the harm caused by ozone can be avoided.

3. Moisture

Although the rubber hoses are waterproof, long-term work in a dark and humid environment or long-term immersion in water will also cause the rubber hoses to age. This is because some auxiliary agents will be added during the manufacturing process of the rubber tube, and some of these auxiliary agents will have water-soluble substances, so if they are in contact with water for a long time, they will be hydrolyzed, which will not only reduce the rubber tube’s Performance, it may also cause damage to the structure of the hose.

4. temperature

Each material of the rubber tube has its own suitable temperature range. General rubber will become hard and brittle when the temperature is too low. This rubber is easy to be damaged and needs to be handled with care. If the temperature rises, UI and vulcanized rubber will cause the unreacted vulcanizing agent in the material to continue to harden. As for non-vulcanized rubber, its properties such as hardness and elasticity will also decrease, which is not conducive to The transportation of materials. Moreover, the increase in temperature will promote the reaction speed of the oxidation reaction between oxygen and the rubber hose, and accelerate the aging of the rubber hose.